Pallet conveyorsFrom individual elements to entire ready-to-use systems

Thanks to our extensive portfolio, Max Dörr GmbH Conveying Systems is your competent partner for solutions in the pallet conveying technology sector. Driven or gravity roller tracks, belt conveyors and belt bends, lifting stations and pallet magazines are just a few examples from our product portfolio.

Whether you use INKA pallets or EUR pallets, lattice boxes, skid or special pallets / steel pallets: we ensure a smooth material flow that you can rely on using our expertise. This comprises transportation, sorting, distribution, buffering and stacking functions, and far more.

- Roller conveyors

- Accumulation conveyors

- Singulation units

- Roller lift tables

- Chain conveyors

- Chain transfers

- Turntables

- Shuttle cars

- Vertical lifts

- Lifting stations

- Contour and profile checking unit

- Pallet stacker/dispenser

- Transportation

- Distribution

- Sorting

- Concatenation

- Buffering

- Storing and removing from storage

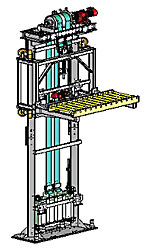

The DÖRR belt lift enables pallets, lattice boxes and special load carriers to be vertically transported across several conveying levels or stories. The maximum load capacity is 1500 kg and the maximum lifting speed is around 1 m/s (greater weights or higher speeds can be accommodated upon request).

The belt lift consists of a sturdy 2-column steel design which is attached to the floor by means of a base plate. Depending on the conveying height, the column design is also bolted to the ceiling penetrations and/or the ceiling structure. The drive unit, which is positioned at the top, consists of a 3-phase gear motor with brake (with pole switching or frequency control), coupling, shifting and drive pulley.

The drive torque is converted into the vertical motion of the lifting sled using two special flat rubber belts and an aramide tension cord running around a drive pulley. A counterweight is used to reduce the drive power.

Even when the lifting sled is operating at high speeds, the Vulkollan-coated guide rollers ensure smooth running. The lifting conveyor belt can be mechanically locked using a rig pin device with limit switch monitoring for maintenance purposes. Depending on the application, the lifting sled can be equipped with a chain or roller conveyor or turntable station. The lifting sled can travel to various pick-up and delivery stations on any number of levels and in both directions, based on the target set. An energy chain ensures that the components arranged on the lifting sled are supplied with electricity via cables. Wiring to a terminal box and a wire mesh guard is available as an option. Further models and special fixtures and fittings are available upon request.

Questions?

We’re here for you:

T +49 (0) 7267 / 9122-0

E info@max-doerr.com