As an owner-managed family company spanning three generations, we bring tradition and innovation together. Thanks to 55 years of experience in plant engineering, we are currently a leading supplier of conveying technology solutions for the internal transportation of piece goods.

A modern fleet of machines, innovative technology, integration-capable solutions, durable concepts and services tailored to each customer have laid the foundations for our success.

Why choose MAX DÖRR

Conveying Systems?

CUSTOM-MADE AND CUSTOMER-SPECIFIC

We provide advice based on your individual needs and manufacture according to specific requests using the latest technology.

LONG-LASTING AND RELIABLE

We are proud to say that our products are Made In Germany and we hold ourselves to the highest standards, which means you can rely on us to provide you with a long lasting solution.

FLEXIBILITY AND SERVICE-ORIENTED

As a medium-sized family company, we are able to react flexibly whenever the customer needs change, thanks to our modern machinery and our own internal service team.

1966

Max Dörr Conveying Systems was founded

In 1966, Max Albert Dörr took a risk and decided to set up his own independent company: Max Dörr Conveying Systems. The company started life with just one other employee, in a former dairy in the village of Richen in Heilbronn.

1968

The move to Gemmingen

As the company expanded and gained more employees, more space was needed. Therefore we built and moved into our first manufacturing hall in Gemmingen, near Heilbronn.

1970

Ascending conveyor for Palmbräu

Our first orders came from our region. For example, the solution we came up with for loading crates of beverages for the local brewery in Eppingen.

1979

Expansion of the manufacturing area

An increase in turnover and rising demand for ever larger and larger systems led to the construction of another manufacturing hall.

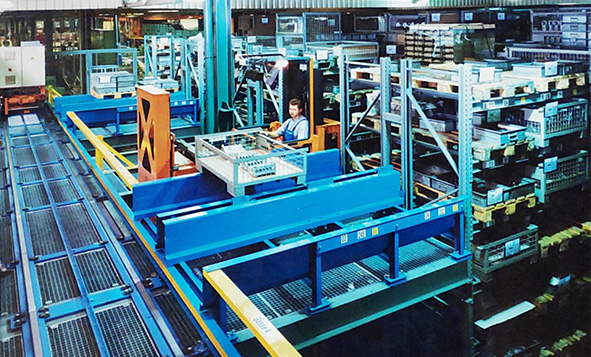

1990

Automation solutions for global stakeholders

Numerous renowned corporations, such as Mercedes-Benz, Volkswagen, Deutsche Bank and many more, rely on the high level of customization and flexibility in our broad range of products. Shown here: pallet conveying technology with telescopic fork lift unit for Bosch.

2001

Founding of Thomas Dörr Cutlery and Kitchen Systems

After developing and successfully presenting a cutlery wrapping system, we recognized the potential in this market and founded a subsidiary. Today, it is a market leader for cutlery polishing machines, glass polishing machines, cutlery wrapping machines, cutlery sorting machines and butter dispensers.

2014

Construction of a new production and warehousing hall.

Due to the sustained success of Max Dörr GmbH and the huge growth of its subsidiary, the company building was expanded.

2022/2023

EXTENSION AND RECONSTRUCTION OF THE OFFICE ADMINISTRATION BUILDING

After a construction period of almost 15 months, the former home of the company founder Max Dörr was expanded and converted into an energy-efficient wooden building that was about twice the size.

2023

Where we are today

From component manufacturing to the entire project planning process, we’re here to act as your contact partner from consultation and planning through design, manufacturing and installation, to regular system adjustment.